Want to cut costs and boost efficiency? Business Process Optimization (BPO) focuses on improving how your company operates by removing inefficiencies, reducing waste, and leveraging tools like AI. Companies can save 15-25% in costs and see productivity gains of up to 35% within a year. Here's a quick breakdown:

- What it is: BPO goes beyond small tweaks, focusing on transformative changes to eliminate inefficiencies.

- Why it matters in 2025: Rising costs and tighter regulations make optimization critical. Only 1% of businesses fully utilize digital transformation.

- AI's role: Tools like Privagent's "Dave the AI Consultant" identify bottlenecks and suggest improvements using real-time data.

- Key steps: Identify weak points, map workflows, and use frameworks like Lean or Six Sigma to refine processes.

Business Process Simplification & Workflow Optimization

Foundations of Process Optimization

Mastering the basics of process improvement is essential for achieving measurable results. These principles serve as the groundwork for refining operations with accuracy and purpose. Let’s break down some key terms and frameworks that support effective process optimization.

Core Concepts and Terms

Bottlenecks are the trouble spots in a process where work slows down or halts entirely, causing delays that affect the entire operation. Picture an order fulfillment center: if packing stations can handle orders faster than the shipping label printer, the printer becomes the bottleneck, holding up the entire workflow.

Throughput refers to the speed at which your process delivers results - like the number of orders completed daily or claims processed weekly. Boosting throughput means achieving more output without needing additional resources.

Key Performance Indicators (KPIs) are metrics that track how well your optimization efforts are working. Examples include average processing time, error rates, or customer satisfaction levels. Similarly, Service Level Agreements (SLAs) establish specific commitments, such as ensuring timely responses to customer inquiries or delivering products within a set timeframe.

Waste represents any activity that uses up time or money but doesn't add value for the customer. This could include overproduction, unnecessary waiting, rework due to defects, or inefficient movement. For instance, a poorly organized manufacturing floor might force workers to waste time walking long distances to retrieve tools.

Process Optimization Frameworks

Several well-established frameworks provide structured approaches to improving efficiency and reducing waste:

- Lean emphasizes cutting out waste and simplifying processes to deliver maximum value to customers.

- Six Sigma uses data-driven strategies to eliminate defects and minimize variability, with a goal of achieving near-perfect quality - defined as no more than 3.4 defects per million opportunities. The DMAIC methodology (Define, Measure, Analyze, Improve, Control) offers a step-by-step guide for tackling problems systematically.

- Kaizen focuses on making continuous, small improvements over time.

- Total Quality Management (TQM) integrates quality assurance into every aspect of the business, making it a shared responsibility across all teams.

Tools like AI-powered analysis, such as insights from Privagent – Dave the AI Consultant, can amplify these frameworks by identifying areas with the most potential for impactful change. Once the right framework is in place, the next step is to pinpoint which processes will benefit most from optimization.

Common Business Processes to Optimize

Customer-facing processes are critical because they directly affect revenue and reputation. Streamlining areas like order processing or customer service can result in faster issue resolution and happier customers.

Operational processes - including inventory management, quality control, procurement, and production scheduling - are the backbone of a business. For example, optimizing logistics can reduce fuel costs and shorten delivery times, improving overall efficiency.

Support processes like HR onboarding, IT ticket resolution, and accounts payable might not be customer-facing, but they still play a vital role. Enhancing these processes can help new employees settle in faster or reduce the time spent on administrative tasks.

To get started, focus on processes that promise clear benefits, whether in terms of cost savings, time efficiency, or customer satisfaction. Begin with high-volume tasks or those with obvious inefficiencies, and use each improvement as a stepping stone for further progress.

Step-by-Step Guide to Business Process Optimization

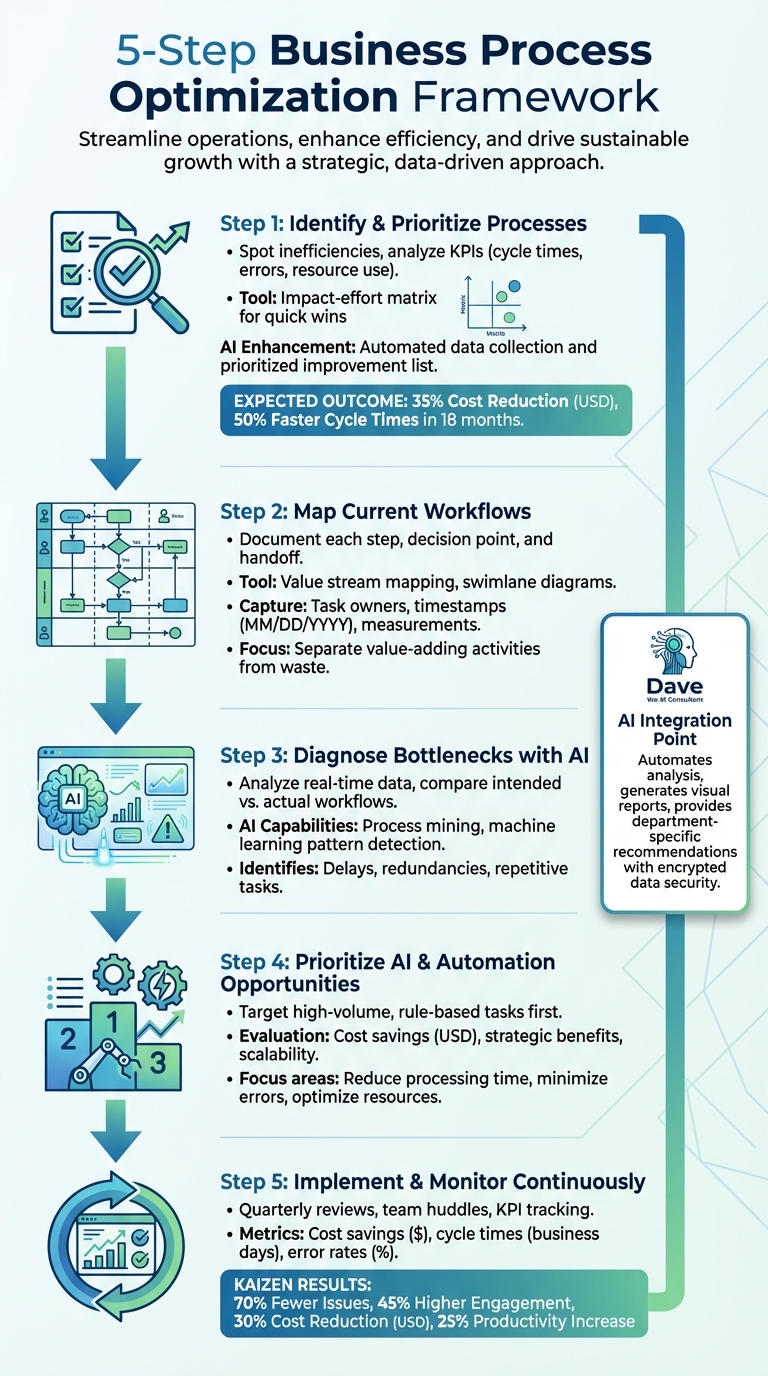

5-Step Business Process Optimization Framework with AI Integration

Turning ideas into actionable results requires a clear, structured plan. Below, we'll walk through the steps to systematically identify, analyze, and improve your business processes, combining traditional methods with AI-driven insights.

Identifying and Prioritizing Processes

Start by taking a close look at your current operations to spot inefficiencies. Focus on pain points like measurable delays, frequent errors, or tasks that don’t add value. Key performance indicators (KPIs) - such as cycle times, customer feedback, and resource utilization - can help you zero in on processes that need immediate attention.

Once you’ve identified problem areas, prioritize them using an impact-effort matrix. This tool evaluates processes based on their potential business impact and the effort needed to implement changes. Processes in the high-impact, low-effort quadrant are your "quick wins" - opportunities to achieve efficiency gains with minimal investment. For example, if your accounts payable process is causing delays and frustrating vendors, automating it could resolve the issue quickly and cost-effectively.

To make informed decisions, calculate your current operational costs in USD and estimate potential savings. For instance, you might project a 35% cost reduction and 50% faster cycle times within 18 months. Beyond cost savings, think about how these processes influence customer satisfaction and employee experience - improvements here often lead to long-term benefits.

AI tools, like Privagent’s "Dave the AI Consultant", can simplify this step. By automating data collection, Dave generates a prioritized list of improvement opportunities, complete with projected time and cost savings. Instead of spending weeks manually gathering data, you can rely on AI to analyze workflow patterns and employee input, saving time and effort.

When high-impact processes are identified, the next step is to break them down and analyze them in detail.

Mapping and Documenting Current Workflows

Visualizing your workflow is essential to understanding where inefficiencies lie. Use tools like flowcharts or swimlane diagrams to document each step, decision point, and handoff. Include details like who is responsible for each task, dates in MM/DD/YYYY format, and measurements in imperial units where applicable.

To separate value-adding activities from waste, try value stream mapping. Walk through the process in real time, noting how long each step takes and where work tends to pile up. For example, if an approval step routinely causes delays, that waiting period is non-value-adding time. Frontline employees are great resources for identifying bottlenecks - they often know exactly where manual data entry slows things down or where retrieving information across multiple systems becomes a hassle.

Once workflows are mapped, AI tools can take the analysis further by uncovering inefficiencies that might not be immediately obvious.

Diagnosing Bottlenecks with AI

With your workflows documented and key issues prioritized, AI tools can step in to pinpoint delays and redundancies. Process mining platforms and machine learning algorithms analyze real-time data to compare intended workflows with actual execution. These tools are especially effective at spotting subtle inefficiencies - like delays caused by repetitive tasks or redundant steps - that are easy to miss during manual reviews.

sbb-itb-5ef22c3

AI in Workflow Diagnostics and Optimization

AI has transformed workflow diagnostics by processing massive datasets in real time, identifying inefficiencies with precision. By analyzing both historical and live data, AI detects patterns, trends, and anomalies that might otherwise go unnoticed - removing the guesswork from decision-making. This is particularly beneficial for U.S. organizations with complex, multi-department operations, where unseen bottlenecks can quietly undermine productivity.

AI Capabilities in Process Optimization

AI leverages historical data - like defect records, activity logs, test results, and production logs - to anticipate potential issues before they escalate. By evaluating variables such as workflow adjustments, team activity, defect density, and test failure rates, AI models highlight high-risk areas, allowing teams to address them proactively. For example, Dave the AI Consultant applies these insights to analyze workflows and provide actionable recommendations tailored to your business operations. This approach not only identifies what needs fixing but also offers practical guidance on how to implement improvements.

How Privagent Simplifies Diagnostics

Privagent enhances the diagnostic process by combining AI analysis with human expertise. It collects employee feedback, creates detailed process maps, and prioritizes areas for improvement. The platform generates visual reports that spotlight inefficiencies, bottlenecks, and automation opportunities. Department-specific summaries offer insights into resource allocation and recommend impactful changes. To ensure data security, all information is managed using encrypted protocols, which is especially critical for U.S. organizations navigating stringent privacy regulations. These targeted insights empower businesses to streamline operations, reduce delays, and foster continuous improvement.

Prioritizing AI and Automation Opportunities

After identifying inefficiencies, the next step is to prioritize improvements based on AI-driven insights. Start with high-volume, rule-based tasks that deliver quick wins before moving on to more complex workflows. When evaluating AI recommendations, consider factors like immediate cost savings, long-term strategic benefits, and scalability across other processes. Targeting areas that reduce processing time, minimize errors, and optimize resource allocation can free up resources for higher-value activities.

Dave simplifies this process by ranking opportunities within a structured framework, offering a clear implementation roadmap. Focusing first on low-complexity, high-return tasks helps organizations build momentum and demonstrate tangible value before tackling more advanced solutions.

Building a Culture of Continuous Optimization

Improving processes isn’t just about quick fixes - it’s about creating a mindset where improvement becomes second nature. This requires resources, active employee participation, and an openness to change. Companies that cultivate a strong culture of ongoing improvement see 50% higher employee involvement in optimization efforts and achieve 35% better long-term results.

Establishing Continuous Improvement Practices

To make continuous improvement part of everyday operations, set up structured practices like quarterly reviews and team huddles. Use these sessions to monitor key performance indicators (KPIs) such as cost savings (in dollars), cycle times (in business days), and error rates (as percentages). For instance, organizations using the Kaizen methodology report impressive outcomes, including:

- 70% fewer process-related issues

- 45% boost in employee engagement

- 30% reduction in operational costs

- 25% increase in productivity

By translating optimization into actionable, measurable steps, businesses can shift from treating it as a vague goal to making it a regular, trackable process.

"Business process optimization is about continuous improvement and progress, not perfection".

Scaling Optimization Across Departments

Expanding optimization efforts across different departments requires a strategic, phased approach. Start by addressing areas with the biggest challenges, pilot the changes, and document insights to guide broader implementation. A great example comes from Rhythm Systems, which introduced a new CRM system in January 2021. They formed a cross-departmental team that met weekly to define needs. Sales and Marketing, facing the most pressing issues, were prioritized. Lessons learned from this initial rollout helped ensure smoother transitions for Finance and Client Services. This phased strategy not only improved client onboarding but also enhanced internal coordination.

When organizations pair optimization efforts with clear communication plans, they see 80% higher employee engagement in process changes. Once optimization is scaled across departments, consistent tracking of long-term results ensures progress is maintained.

Measuring Long-Term Impact

After rolling out optimization initiatives, tracking long-term metrics is crucial to validate their success. Focus on KPIs like cost savings (in dollars), productivity improvements, and shorter cycle times. Clearly defined metrics - such as reduced errors, faster delivery, and higher customer satisfaction - make it easier to evaluate progress. ROI assessments should include both immediate benefits, like lower labor costs, and longer-term gains, such as better employee morale and faster innovation.

A before-and-after comparison provides clear evidence of success:

| Metric | Before Optimization | After 12 Months | Improvement |

|---|---|---|---|

| Average Cycle Time | 8.5 business days | 4.2 business days | 51% reduction |

| Monthly Operational Costs | $125,000 | $87,500 | $37,500 saved (30%) |

| Error Rate | 12.3% | 4.1% | 67% reduction |

| Employee Engagement Score | 62% | 81% | 19-point increase |

These results not only highlight the benefits of continuous optimization but also reinforce the importance of sustained investment in these efforts. By consistently measuring outcomes, businesses can ensure that improvements stick and continue to deliver value over time.

Conclusion

Improving business processes isn’t a one-and-done task - it’s a continuous effort. By refining key workflows, companies can achieve better efficiency, faster turnaround times, and fewer mistakes.

Thanks to advancements in AI, businesses now have tools that do more than just automate tasks. AI-powered systems can monitor operations in real time, uncover patterns, and make instant adjustments to improve performance. This evolution shifts the focus from merely following steps to actively achieving desired outcomes, helping businesses stay agile without sacrificing precision.

Privagent’s Dave the AI Consultant offers a step-by-step guide to process improvement. Instead of taking shots in the dark, businesses get targeted recommendations on where to focus and how AI can deliver measurable results.

The key is to start with small, manageable changes, track their impact, and gradually expand. This approach not only boosts efficiency and reduces costs but also enhances customer satisfaction. Companies that embrace ongoing improvement often see more engaged employees and stronger long-term success.

FAQs

How does AI help optimize business processes?

AI plays a transformative role in improving how businesses operate by taking over repetitive tasks, analyzing massive datasets to uncover actionable insights, and simplifying workflows. This allows companies to pinpoint inefficiencies, anticipate trends, and manage resources more effectively.

With AI tools in place, businesses can boost employee productivity, tailor customer experiences to individual preferences, and cut operational costs. These solutions not only save valuable time but also enable businesses to grow efficiently without compromising on quality.

What’s the difference between Lean, Six Sigma, and Kaizen in business process optimization?

Lean, Six Sigma, and Kaizen are three well-known strategies for refining business processes, each with a unique focus:

- Lean targets the removal of waste in workflows to boost efficiency and deliver maximum value.

- Six Sigma zeroes in on minimizing defects and reducing variability by relying on data analysis and statistical tools.

- Kaizen promotes continuous improvement through small, gradual changes, encouraging steady progress over time.

While Lean and Six Sigma are often outcome-driven, focusing on areas like efficiency or quality, Kaizen nurtures a culture of ongoing improvement, inviting contributions from everyone within the organization.

What are the best ways to measure the success of process optimization efforts?

The effectiveness of process optimization can be gauged through key performance indicators (KPIs) that highlight gains in efficiency and outcomes. Here are some commonly tracked KPIs:

- Cycle time: Measures the total time it takes to complete a process from start to finish.

- Defect rates: Tracks the percentage of errors or issues occurring within a process.

- Productivity: Assesses output relative to input, such as tasks completed per hour.

- Customer satisfaction: Reflects feedback and ratings provided by customers.

- Cost efficiency: Evaluates reductions in expenses tied to the process.

Regularly monitoring these metrics helps businesses pinpoint successful strategies, address weak spots, and ensure their optimization efforts lead to tangible, measurable improvements.